This course has been discontinued.

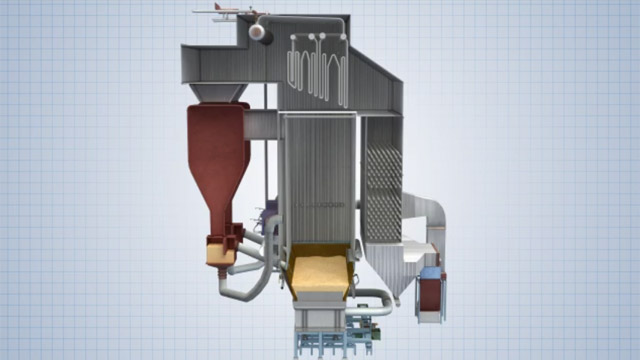

Conventional solid fuel power boilers burn the fuel in a fixed bed. In a fluidized bed boiler, hot air is blown at a high velocity up through a bed of sand, limestone, and ash causing the solid particles to fluidize, or behave like a liquid. Fluidization provides good mixing and allows for effective combustion when fuel is added. Fluidized bed combustion (FBC) provides several advantages for burning solid fuels, including higher efficiency, lower emissions, and the ability to burn low quality (e.g. high moisture) fuels. This course will focus on the operation of bubbling and circulating fluidized bed boilers.

•Describe the advantages and disadvantages of fluidized bed boilers

•Differentiate between bubbling and circulating fluidized bed boilers

•Describe the operation of both fluidized bed boiler types

•Identify and describe the function of the key components of both fluidized bed boiler types

•Define conduction, convection, and radiation and describe how heat is transferred in boilers

•Describe how fluidized bed boilers can reduce emissions

•Describe safety guidelines for working around boilers

Industrial Libraries

- Convergence Industrial Maintenance Library

- Industrial Complete

- Industrial Power Generation

- Industrial Premium